Unlocking the Secrets to Efficient Lift Repair Works: Expert Insights Revealed

In the realm of lift repair and maintenance, revealing the techniques that bring about reliable and reliable service is akin to figuring out a complex puzzle. Specialist understandings offer as the directing light through the maze of obstacles dealt with by maintenance professionals in the upright transport market. By delving right into the midsts of aggressive techniques, fixing techniques, and the constant quest of skill enhancement, the path to elevating maintenance standards exposes itself. As we start this journey to demystify the keys behind streamlined lift repair work, a world of possibilities arises, guaranteeing a future where downtime is reduced, safety is focused on, and functional quality ends up being the norm.

Typical Lift Repair Work Challenges

An additional widespread challenge in lift repair services is the absence of appropriate maintenance records. Without accurate maintenance records, repair technicians may battle to diagnose concerns effectively or prepare for prospective troubles. This can lead to longer repair times and boosted prices as technicians function to fix concerns without historical data to guide them.

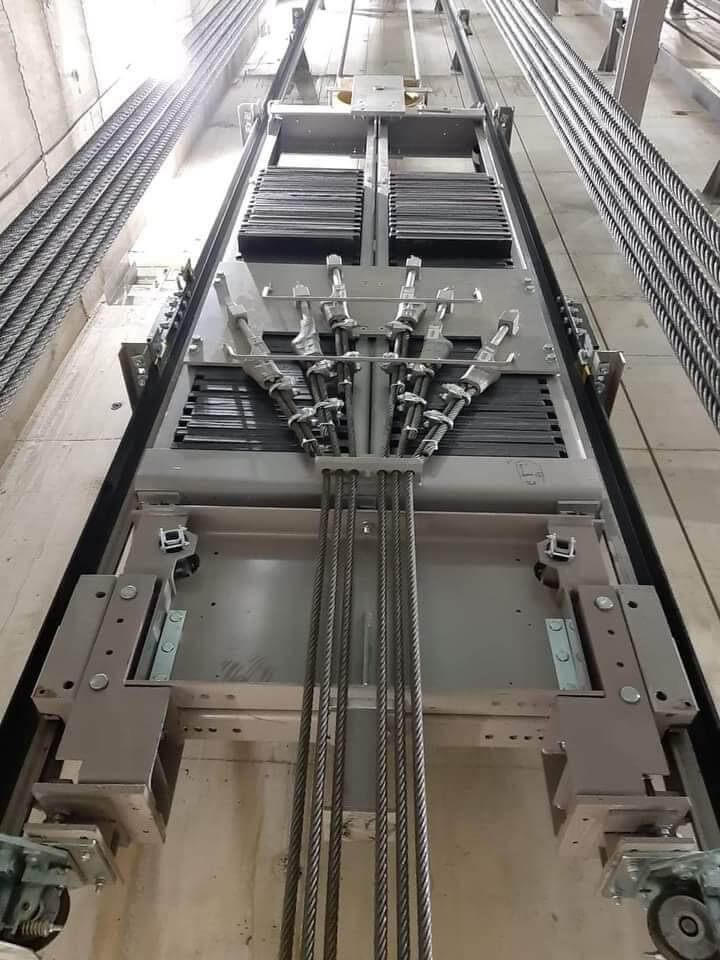

Additionally, availability issues within lift shafts can present considerable difficulties during repairs. Limited space, uncomfortable angles, and intricate machinery can make it tough for service technicians to get to the essential components for repair, prolonging the overall repair work procedure - Lift Maintenance Repair. By attending to these common difficulties proactively, lift repair service experts can boost functional performance and make certain the smooth functioning of vertical transport systems

Proactive Upkeep Strategies

Carrying out aggressive upkeep techniques is paramount for making sure the longevity and optimal performance of lift systems. By adopting an aggressive strategy to maintenance, structure supervisors and lift upkeep teams can deal with possible problems prior to they escalate into pricey repairs or downtime. One efficient strategy is to develop a normal upkeep routine that consists of detailed assessments, lubrication of moving components, and testing of safety features.

Furthermore, purchasing training programs for maintenance team can improve their skills in identifying prospective issues and carrying out precautionary upkeep tasks efficiently - Lift Maintenance Repair. By empowering upkeep teams with the understanding and devices required to proactively maintain lift systems, building proprietors can decrease disruptions, prolong the life expectancy of their lifts, and ensure a risk-free and reliable upright transportation experience for residents

Repairing Strategies

Efficient troubleshooting techniques are vital for without delay recognizing and dealing with issues with lift systems to decrease downtime and ensure ideal performance. When confronted with a lift breakdown, systematic troubleshooting is essential to determine the root reason properly. One reliable method is to begin with a comprehensive aesthetic assessment of the lift components, examining for any type of visible indications of damage, imbalance, or wear. Additionally, making use of diagnostic tools and software application can aid in determining sensor-related or digital issues that may not be quickly apparent.

Enhancing Repair Service Skills

Enhancing effectiveness in lift system fixings is a basic aspect of ensuring ideal capability More about the author and minimizing operational disturbances. Lift professionals should consistently work with developing their repair skills to satisfy the demands of contemporary lift systems. One key technique for boosting fixing abilities is routine training sessions that focus on both theoretical understanding and useful application. These sessions can cover a variety of subjects such as brand-new innovations in the market, fixing complicated concerns, and security protocols. Additionally, specialists can gain from hands-on experience under the advice of seasoned professionals to enhance their analytic capacities and decision-making abilities in real-time repair work scenarios.

Moreover, remaining updated with the most current improvements in lift technology is important for specialists aiming to enhance their repair work skills. This includes actively looking for details about new components, software program updates, and maintenance methods to why not try this out successfully diagnose and remedy issues. By spending time and initiative right into constant knowing and practical experience, lift service technicians can dramatically enhance their repair work competencies and add to the effective performance of lift systems.

Boosting Upkeep Criteria

Boosting maintenance standards in lift systems is vital for making sure prolonged functional effectiveness and safety. Normal maintenance not only improves the performance of lift systems yet likewise decreases the threat of unanticipated malfunctions and makes certain the safety of customers. By sticking to strict upkeep methods, lift owners and drivers can substantially decrease the probability of costly repairs and downtime.

Executing a comprehensive maintenance routine that includes click here for more info routine examinations, lubrication of moving components, and aggressive substitute of used elements is essential. Making use of sophisticated technologies like IoT sensing units and predictive upkeep software application can help in checking the lift's problem in real-time, enabling prompt interventions prior to issues rise. Furthermore, giving constant training for maintenance staff on the most current industry criteria and best techniques is important for promoting maintenance quality.

Moreover, cultivating a culture of responsibility and focus to detail among maintenance groups can further elevate maintenance criteria. Urging open communication channels for reporting and resolving maintenance issues immediately can aid in maintaining a high level of lift system reliability. Eventually, by focusing on and boosting maintenance standards, lift systems can operate efficiently and safely for a prolonged period.

Final Thought

In verdict, reliable lift fixings require proactive maintenance techniques, troubleshooting methods, and improved repair work skills. By attending to typical difficulties and raising maintenance standards, maintenance specialists can properly make certain the smooth procedure of lifts - Lift Maintenance Repair. Applying these specialist insights can result in improved efficiency, reduced downtime, and raised safety and security for both travelers and devices

In the realm of lift repair and upkeep, discovering the approaches that lead to efficient and effective service is akin to decoding an intricate challenge.Another widespread difficulty in lift repair work is the absence of appropriate maintenance documents. By embracing a positive approach to maintenance, structure supervisors and lift maintenance groups can deal with prospective issues prior to they escalate right into costly repairs or downtime.In final thought, efficient lift fixings need proactive upkeep strategies, repairing methods, and boosted repair work abilities. By raising and addressing typical challenges maintenance criteria, maintenance experts can effectively make sure the smooth procedure of lifts.